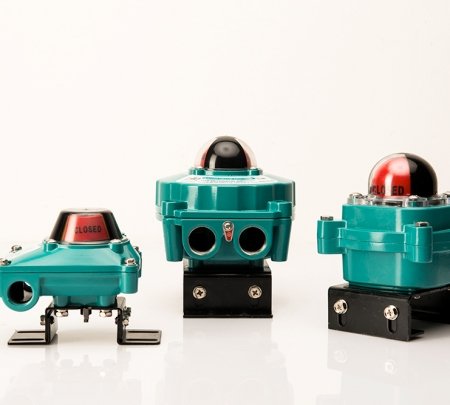

Description

PAC-S Series Pneumatic Actuator is designed suitable for general purpose of valves and damper automation and offer a wide range of torques enable to operate ball, butterfly, plug valves, dampers or any device that requires a quarter turn operation for on-off or modulating service. Scotch Yoke actuators are available with symmetric yokes. Asymmetric yoke provide more constant torque throughout – at both the break points and end positions.

Specification

- Comply to UNI EN 15714-3:2009 standard

- ISO Connection Standard:UNI EN ISO 5211

- Auxiliary Connectioin:NAMUR

- Control Angle:90°

- Torque:Relative to control pressure. Please refer to torque selection table.

- Coating Protection:Hard anodized surface, epoxy powder coated end cap. Surface coating can be customized.

Working Conditions

| Working Temperature | Standard:-20℃~+80℃

High Temperature:-20℃~+150℃ Low Temperature:-50℃~+60℃ |

| Supply Pressure | Min. 2 bar, Max. 8 bar |

| Working Medium | Filtered and dry compressed air or inert gas, without needing lubricant |

Features And Benefits

1.Provide with the self-lubricated bearing and guide ring between the sliding parts.

- Less friction between piston and cylinder

2.Both pin, yoke and bearings are made of Alloy Steel , the hardness is higher than 50 HRC .

- Effective resistance to the actuator internal dynamic wear;

3.Rolling friction between yoke and bearing

- Reduced the friction between the piston and shaft;

4.Scotch yoke with rolling friction (transforming rotary motion into linear motion using piston and shaft without teeths/gears)

- Reduced friction between piston and shaft with consequently less wear on the relevant parts

- High opening and closing torques provided by scotch-yoke concept;

- Compared with rack and pinion actuator, reduced actuator volume (30%) and installation space;

- Compared with rack and pinion actuator, reduced actuator weight (30%) and construction of equipment’s.

- Compared with rack and pinion actuator, reduced the air consumption ( 40% )

- Faster switching speed than rack and pinion actuator(40% for double acting,20% for single acting)

5.Cylindrical cylinder

- Reduced wear of the sliding piston parts with low roughness of the surface.

6.SIL3

- Meet the requirements of SIS and guarantee the highly reliable and safe operation

7.ATEX Certificate

- Allow products to be installed in the potential explosive environments.

Options

- Direct mount solenoid valves

- Monitor/Position confirmation limit switches

- Electro-Pneumatic positioner 4-20m input

- Pneumatic positioners 3-15 PSI input