Flow Indicators and Industrial Applications

Flow indicators are devices that provide a visual means of observing liquid or gas flow within pipelines. Unlike flowmeters, which measure the quantity of flow, flow indicators are designed to confirm the presence, direction, and sometimes the quality of flow. They play a simple yet crucial role in process safety, maintenance efficiency, and fault detection.

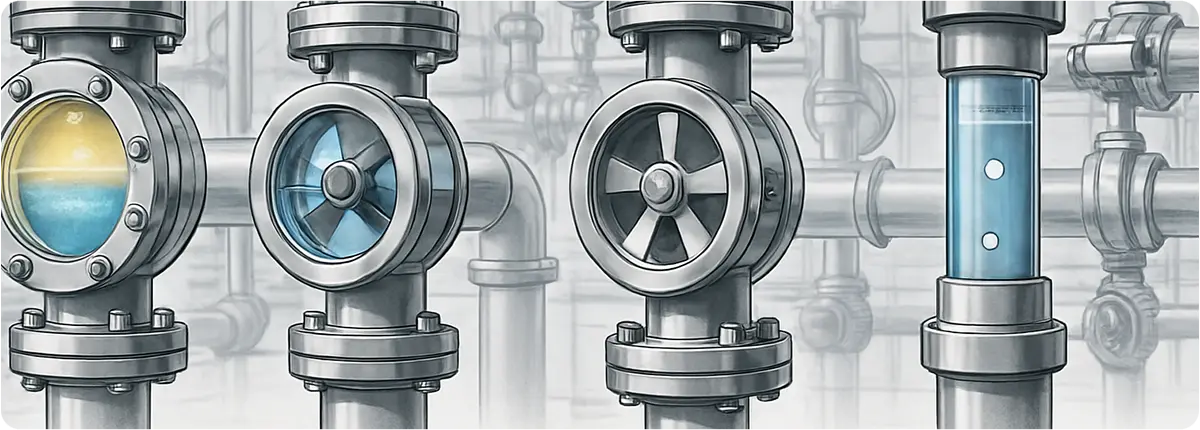

WORKING PRINCIPLE AND TYPES

- Sight Glass Indicators: Transparent glass or plastic tubes mounted on pipelines for direct visual observation.

- Paddle Type Indicators: A mechanical paddle rotates or moves with the flow.

- Gear/Turbine Indicators: Flow is confirmed through the rotation of small gears or turbines.

- Bubble Type Indicators: Gas flows are monitored by observing bubble movement.

TECHNICAL FEATURES AND SELECTION CRITERIA

- Material selection: Borosilicate glass, stainless steel, PTFE

- Pressure and temperature resistance

- Connection types: flanged, threaded, welded

- Optional features: illumination, dual-sided viewing

ADVANTAGES AND LIMITATIONS

Advantages:

- Simple and cost-effective design

- Quick visual confirmation of flow

- Easy maintenance

Limitations:

- Does not provide precise flow measurement

- Limited use with high-pressure or hazardous fluids

- Observation windows may become contaminated over time, requiring cleaning

APPLICATION AREAS

- Pump outlet monitoring in water and wastewater treatment plants

- Flow verification in chemical and petrochemical processes

- Hygienic pipeline monitoring in food and pharmaceutical industries

- Cooling water flow monitoring in HVAC systems

STANDARDS AND SAFETY

- ASME BPE: Standards for hygienic process equipment

- ISO 9001: Quality assurance practices

- Sight glass design requirements for pressurized vessels

CONCLUSION

Flow indicators are critical devices for enhancing process safety and simplifying maintenance in industrial plants. Modern versions can be integrated with digital sensors, allowing connectivity to SCADA systems, thus combining visual monitoring with advanced process control.

Convalve

Convalve Convalve

Convalve