Globe Valves

Globe valves are important in systems that control fluids. Known for their varied uses and precise control, they are used in many industries. Let’s delve into how they work, their benefits, and where they are used.

HOW THEY WORK :

Globe valves have a round shape and use a moving part called a plug or disc to control the flow of fluid. The plug moves up and down when you turn the handwheel, opening or closing a hole (orifice) in the valve. Because of this, you can adjust the flow very precisely. The main parts of a globe valve include the valve body, handwheel, bonnet, a threaded stem, and the plug.

WHY USE GLOBE VALVES ?

- Precision: They are great for applications needing exact control of fluid flow.

- Reliable Shut-Off: The up-and-down movement of the plug ensures a tight seal, which helps prevent leaks.

- Versatility: They can be used both for fully stopping the flow (shut-off) and for slowing it down (throttling).

- High-Pressure Tolerance: Good for use in conditions where the fluid is under high pressure.

WHERE YOU’LL FIND THEM :

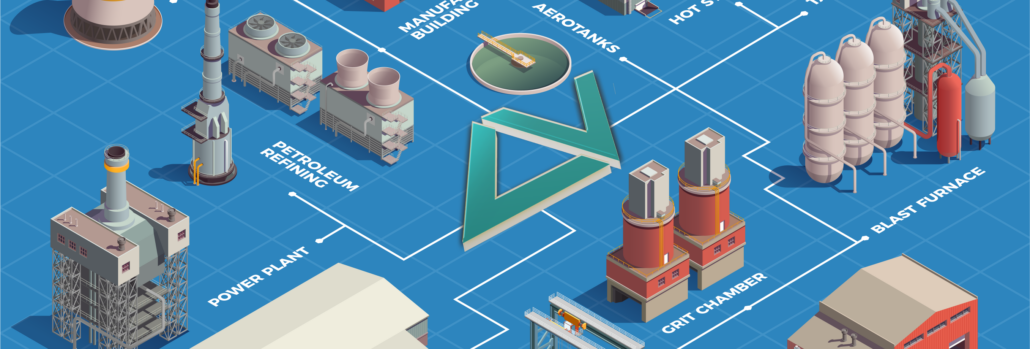

Globe valves are common in different industries:

- Oil and Chemicals: Used in refineries and pipelines.

- Power Plants: Controls steam and water in power generation.

- Water Treatment: Manages flow of water and chemicals.

- Climate Control: Used in HVAC systems to manage water and steam.

DESIGN VARIATIONS :

Different designs can affect the fluid’s ease of flow:

- T- or Z-Types: Standard, but provide higher resistance to flow.

- Y-Types: Allow for smoother flow.

- Angle Types: Change the direction of the flow only once, reducing resistance.

MANUAL OR AUTOMATED :

Though often operated manually, you can also automate them. You can use air pressure (pneumatic) or electricity to move the plug or disc up and down.

CONCLUSION :

Globe valves offer a reliable and flexible way to control fluid flow. They are useful in a variety of settings, from oil refineries to HVAC systems. Depending on your specific needs, a globe valve could be the right choice for efficient and smooth operation.

Convalve

Convalve Convalve

Convalve