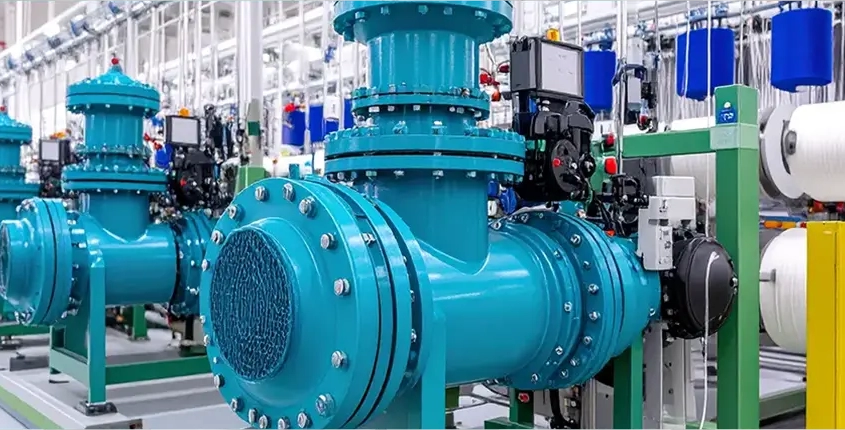

High-Performance Valve Solutions for Textile Machinery: Reliability in Heat and Corrosion

THE ROLE OF VALVES IN TEXTILE MACHINERY

The textile industry relies on complex machinery for processes such as weaving, dyeing, finishing, and printing. Among these, dyeing machines stand out for their intensive use of valves. In these systems, valves control the flow of water, steam, and chemicals, ensuring precise process control and consistent product quality.

Dyeing operations require rapid and accurate adjustments in temperature, chemical dosing, and water circulation. This demands valves that can operate reliably under high-frequency use and harsh operating conditions.

HARSH OPERATING CONDITIONS: HEAT AND CORROSION

Valves in textile dyeing machines face two significant challenges: high temperatures and corrosive environments. Steam heating processes can expose valves to extreme heat, while dyeing chemicals, salts, and detergents create highly corrosive conditions.

Two valve types are most commonly used in these applications:

-

Angle Seat Valves – Known for their fast actuation, excellent flow rates, and durability under high-temperature steam and liquid service. Ideal for automated control in textile processing lines.

-

Butterfly Valves – Used for larger pipelines, offering efficient on/off control and throttling capabilities. When made from corrosion-resistant materials, they provide long service life in harsh dyeing environments.

Convalve angle seat and butterfly valves are engineered with high-grade stainless steel, PTFE seals, and advanced actuator technology to withstand both thermal stress and chemical attack.

CONVALVE’S EXPERIENCE IN TEXTILE INDUSTRY PROJECTS

For decades, Convalve has supplied robust valve solutions to textile manufacturers around the world. Our valves are trusted in:

-

Large-scale dyeing plants in Asia, where precise temperature and chemical control are essential for fabric quality.

-

European textile finishing facilities using Convalve butterfly valves in high-capacity water circulation systems.

-

Integrated textile mills in the Middle East relying on angle seat valves for automated, high-speed dyeing operations.

By combining corrosion resistance, thermal durability, and reliable automation, Convalve valves help textile producers achieve consistent quality, maximize uptime, and reduce maintenance costs.

Convalve

Convalve