Magnetic Flowmeters and Industrial Applications

Magnetic flowmeters, also known as electromagnetic flowmeters, are precision instruments based on Faraday’s law of electromagnetic induction. They are used to measure the flow velocity of conductive liquids and are widely applied in water, wastewater, chemical, food, pharmaceutical, and power industries.

WORKING PRINCIPLE

When a conductive liquid passes through a magnetic field, a voltage is induced, which is directly proportional to the fluid velocity. According to Faraday’s law:

E = B · d · v

Where E is the induced voltage, B is the magnetic flux density, d is the distance between electrodes, and v is the average fluid velocity.

The flow rate is then calculated as:

Q = v · A

Q: flow rate, v: velocity, A: pipe cross-sectional area.

STRUCTURAL FEATURES

- Measuring tube: stainless steel or lined with PTFE/rubber

- Electrodes: corrosion-resistant alloys (316SS, Hastelloy, titanium)

- Magnetic field: generated by coils

- Output: 4-20 mA, HART, Profibus, Modbus, digital displays

ADVANTAGES AND LIMITATIONS

Advantages:

- No moving parts, low maintenance

- High accuracy (0.2% – 0.5% error)

- No pressure loss

- Applicable to a wide range of pipe sizes

Limitations:

- Only works with conductive liquids (σ > 5 µS/cm)

- Not suitable for gases, oils, or low-conductivity fluids such as pure distilled water

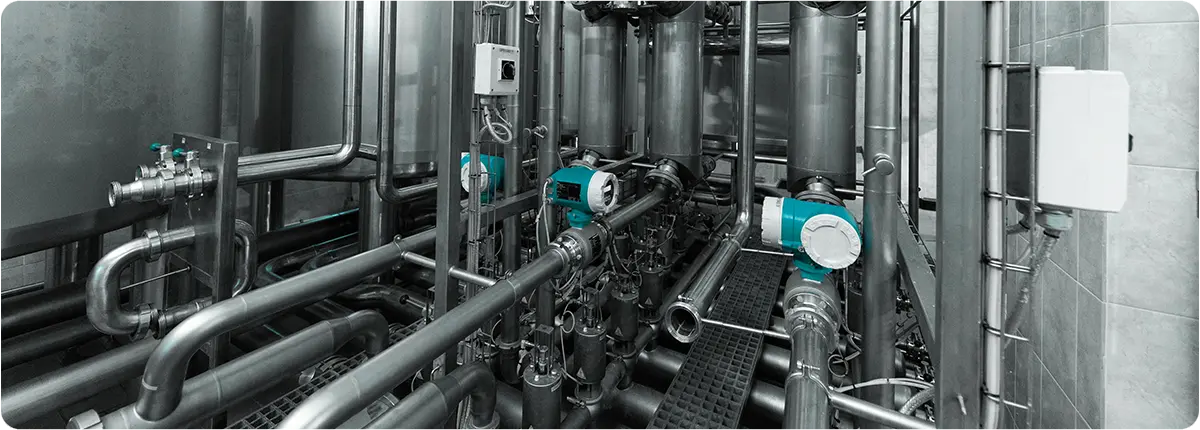

APPLICATION AREAS

- Water and wastewater flow monitoring

- Chemical industry for acids, bases, and solution measurement

- Hygienic flow monitoring in food and beverage industry

- Pharmaceutical process flow control

- Cooling water monitoring in power plants

STANDARDS AND CALIBRATION

- ISO 6817: Standard for electromagnetic flowmeters

- OIML R 117: International standard for liquid measuring devices

- ATEX-certified versions: For explosive environments

- Regular calibration is essential to ensure accuracy

CONCLUSION

Magnetic flowmeters play a crucial role in modern industries by providing accuracy, reliability, and low maintenance for conductive liquid measurements. Their digital communication capabilities make them easy to integrate into automation systems for process optimization and control.

Convalve

Convalve Convalve

Convalve