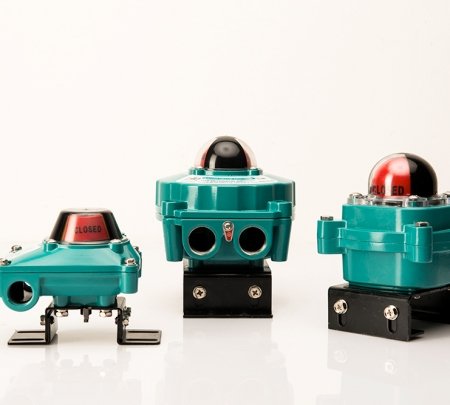

Description

Convalve EAC 1 Electric Actuator stands out with its aesthetically optimized design, superior performance characteristics, lightweight construction, and high output torque. The internal and external surfaces of its housing are cleaned with ozone during manufacturing and subsequently coated with an epoxy-based powder paint to enhance corrosion resistance. Convalve EAC 1 Electric Actuator complies with international standards and is rated at IP67. Its flange connection dimensions fully adhere to the ISO 5211 standard, and the connection shaft housing is designed for on-site replacement, offering significant advantages in machining and assembly.The product features an integrated self-locking mechanism and an infinite (helical) gear configuration with externally adjustable mechanical limit elements. The motor windings include an integrated thermal protection system to prevent overheating. Additionally, the position indicator is equipped with a lens-enhanced design to ensure clear and accurate valve position monitoring. The electronic control circuitry is optimized to deliver high efficiency and performance tailored to evolving and customized user requirements. Optionally, the system can be integrated with a proportional control unit (modulation unit) to provide both on/off and modulating control options.

Features

- Quarter turn (90°) operation with mechanical travel stops

- Rugged type nema 4X weatherproof aluminum alloy enclosure

- Highly visual valve position indicator

- Manual override

- ISO5211 multi-flange valve mounting

- Heavy duty motors with overload protection

- Thermostatically controlled anti-condensation heater

- Two auxiliary limit switches included on base units

- Self-locking all metal gear train, no additional brake required

- Electronic Positioner models available for modulating type

Applications

Industrial quality electric actuators typically used to automate quarter turn (90º) ball valves, butterfly valves and dampers. The EAC 1 series actuator is quick and easy to install with standard ISO5211 multi-flange mounting and a double square drive.

Operation

Electric actuator uses power-to-open and power-to-close, stays in the last known position with loss of power. On receipt of a continuous voltage signal, the motor runs and via a rugged all metal gear system rotates 90º. The motor is automatically stopped by internal cams striking limit switches. On receipt of a reversing continuous signal, the mo- tor turns in the opposite direction reversing the output drive position.Modulating actuators with electronic positioner use an analog input signal to control the drive output position. Rugged self-locking all metal gear train eliminates the need for additional braking.