Description

It is a flow measurement method based on the electromagnetic field principle. There are 2 coils inside each electromagnetic flowmeter. With the help of metal parts placed on these coils, it creates a continuous magnetic field across the cross-sectional area of the measuring tube. The 2 electrodes that sense the voltage are placed inside the measuring tube perpendicular to each other. The insulating material coated on the inner surface prevents the formation of short circuits between the conductive liquid and the metal measuring tube.

In the absence of flow, no electrical tension occurs between the 2 electrodes, the negatively and positively charged ions in the conductive liquid are equal in the liquid. With the initiation of flow, the magnetic field exerts a force on the charged ion particles in the liquid. As a result, the negatively and positively charged ions in the liquid separate from each other and head to opposite sides of the measuring tube. At the end of this situation, an electrical voltage is formed which is sensed by the electrodes.

This voltage is directly proportional to the flow rate in the line. Instant flow can be calculated with the known volume and velocity information of the measuring tube. As the flow rate increases, the separation of the charged particles will increase and the voltage between the electrodes will also increase. The measuring electrodes can also detect magnetic noise in the environment from time to time, this noise signal must be strictly distinguished from the actual measurement signal. To achieve this, the magnetic field must be created with a pulsed direct current.

By constantly changing the places of the charged ions between the electrodes with a direct pulsed current, the effect of magnetic noise is eliminated and precise and stable flow measurement is made. In the simplest way, the Electromagnetic Measurement principle and the Flow rate information are calculated with the above-simplified formula.

In order to provide sensitivity under ideal conditions, the following conditions must be met.

- The tested liquid must have electrical conductivity.

- The pipe must be full.

- The components in the liquid must be homogeneously mixed.

- If the liquid is magnetically induced, the magnetic field of the device will change and therefore the device needs to be adjusted again.

- There should be appropriate straight pipe spacing.

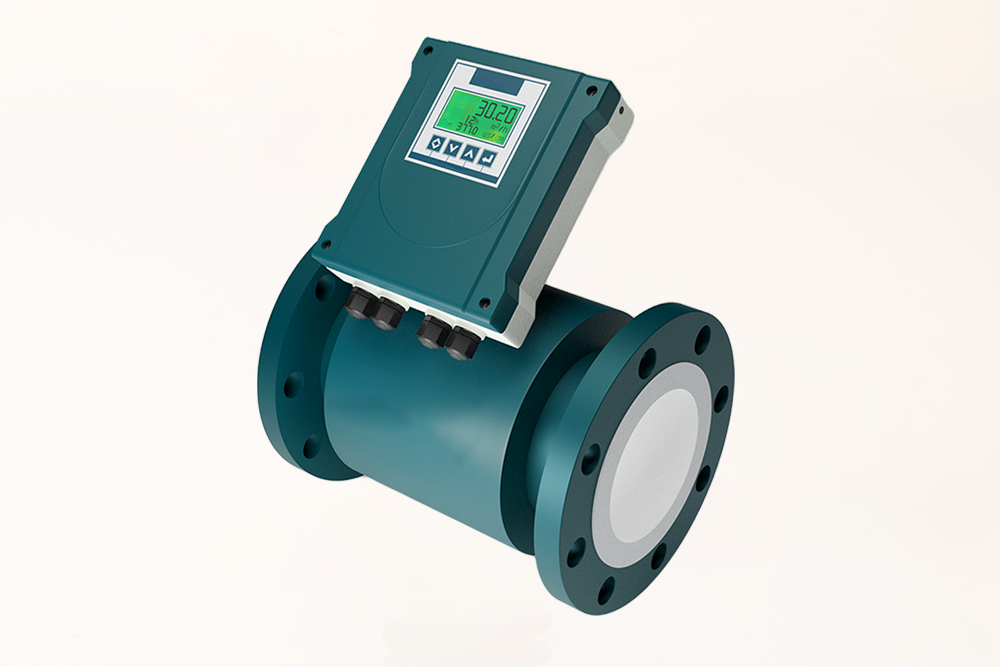

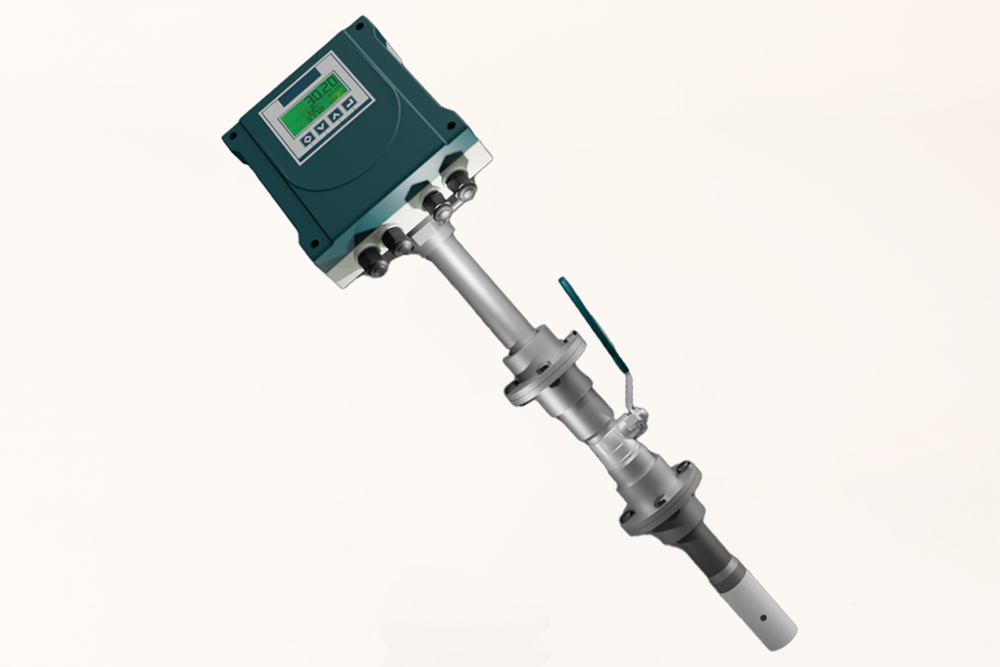

Features

| MEASURING RANGE | 0.05m/s… 15m/s |

| MEASUREMENT FIELD | Conductive Liquids |

| BODY MATERIAL | ST37 Black Steel + Corrosion Resistant Paint |

| SENSOR MATERIAL | SS316L Ops: S5304, Hastelloy C, Hastelloy B, Titanium, Tantalum, Platinum |

| INNER COATING | Teflon (PTFE) or Hard Rubber (Rubber) |

| PRECISION | 0.5% or 0.25% (Türkak Accredited) |

| TEMPERATURE | -10°C … +60°C Rubber / -20°C … + 150°C Teflon |

| MOISTURE | 5%-95% |

| MEASURABLE MIN. CONDUCTIVITY | 20 µs / cm Water 5 µs / cm other Liquid |

| CONNECTION | Flange Connection, Ops: Clamb Connection |

| PRESSURE | PN 6/10/16/25/40/63/100, Class 150/300 |

| PROTECTION CLASS | IP67 Compact Type / IP68 Remote Type |

| FEED | 85-265 VAC 50 Hz or 24VDC, Opt. Battery operated |

| GROUND | Grounding Electrode Included |

| OUTPUT | Pulse / Frequency / 4-20Ma / RS485 Modbus / 2 X Transistor Alarm (Programmable) / Opt. HART |

| INDICATOR | 3×16 Backlit LCD Displaying lnstant or Total Flow |

| ALARMS | Empty Pipe, Sensor Error, Over Limit |

| REPORTING | Daily, Weekly, Monthly and Annual total flow (negative / positive / net) |

| SAMPLING RATE | It can be selected from 0.2 to 100 seconds. |

Advantages

- There are no mechanical parts that prevent the flow or reduce the pressure.

- Measuring scale; 10 times more than other flow meters.

- All measurements and adjustments can be made/displayed via the integrated or wall-mounted LCD display.

- It can be composed according to the process and fluid with the user interface. (Density setting can be Inputed.)

- The menu can be protected with a password.

- Instant and total flow can be observed on the LCD screen at the same time.

- With the report feature, old data can be examined. (Daily, weekly, monthly, yearly.)

- Total flow can only be reset with a password.

- Flow rates between 0.05 and 15 m/s can be measured and the speed can be monitored on the LCD screen.

- Calibration (in a fully filled and stable fluid-filled pipe) can be done with the menu.

- Measurement accuracy can be achieved at 0.2%

- Conductivity measurements can be made and displayed on the LCD screen.

- It can take measurements in all homogeneous conductive liquids above 5 uS.

- It provides resistance to environmental electronic noises through its grounding electrode.

- Thanks to its flange connection, it provides a reliable, easy and long-lasting assembly feature.

- Thanks to its metal body, it is protected against external factors.

- Measurement stability has been significantly increased.

- Even with low conductivity and high density, the measurement response speed is greatly increased.

- Electrode material safety has been increased to the highest level.

- With the DN15-DN2200 production facility, lead times have been minimized.

- The LCD display resolution has been increased.

- The product electronics have been revised to make it better, more stable, and more robust.

- Technical support capacity has been increased and failure support and resolution times have been shortened.

- With our new calibration facility, TÜRKAK accreditation provides a wide range of services from DN15 to DN2200.

Applications

- Water and Wastewater lndustry

- Food and Beverage lndustry

- Pharmaceutical and Cosmetic lndustry

- Chemical lndustry

- Paper lndustry

- Mining and Energy lndustry

- Agriculture

- Machinery Manufacturing lndustry

- Mining lndustry

- Energy lndustry

- Oil lndustry