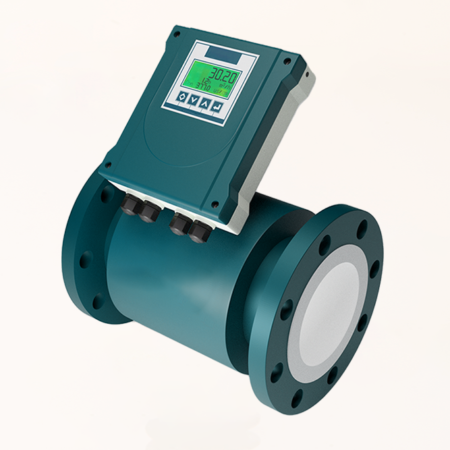

Description

Vortex flowmeters operate based on the KARMAN principle. it provides an advantage to the user tor massive and volumetric flow measuring of some fluids such as liquids, gases, and steam. With this product, measurements can be taken with an accuracy of 0.5% in liquid measurements and 1.0% in gas and steam measurements. For fewer error rates, high sensitivity of up to 0.2% can be achieved by precise calibration in our ISO 17025-certified calibration laboratories.

In the measurement logic based on the Von Karman Vortex path principle, the flow is divided into 2 by the effect of the object placed in the direction perpendicular to the flow and eddies rotating in the opposite direction are created. The frequency of these eddies, which propagate in waves, is measured.

Via the sensor in the vortex flowmeters (piezoelectric element) measures the speed by counting the frequencies, and the flow rate with the result of mathematical calculations. These measured frequencies are proportional to the amount of flow.

Pressure and temperature data are used directly in mathematical calculations, especially since they directly affect the density in the mass flow measurement of gas fluids. For cases where these 2 values are variable, the compensated model is preferred and the changing density is also calculated to provide accurate flow measurement.

Features

| INPUT | 12-32 VDC |

| SUBSTANCE | Liquid, gas, steam |

| ACCURACY | 0.5% Liquid 1.0% Gas, 0.2% with optional calibration |

| MEASURING RANGE | 0.3-7 m/sn liquid |

| 2-70 m/sn gas | |

| CONNECTION | Flanged Connection |

| Wafer Connection | |

| INDICATOR | LCD Display |

| PRESSURE RANGE | 4-100 Bar ( Standard 6/10/16/25 Bar) |

| AMBIENT TEMPERATURE | -20°C +70°C LCD DISPLAY |

| -40°C +85°C without display | |

| MOISTURE RESISTANCE | %5-%95 Rh |

| OPERATING TEMPERATURE | -50°C +250°C |

| -100°C +350°C High Temperature Model | |

| OUTPUT | 4-20mA ops. HART Display Model |

| Model without Pulse Indıcator | |

| Ops. RS485 Modbus | |

| ADJUSTABLE SECTIONS | Flow mode, flow unit, scale, density, indicator data. |

| ALARM | Low Flow Alarm (3.8 mA ), High Flow Alarm (22 mA} |

| CALIBRATION | 2/5 point K-factor Correction |

| INDICATOR | 1. Line Flow Rate |

| 2. Line Total Flow | |

| 3. Line Flow, Current, Temperature, Pressure, Density % | |

| COMPENSATION | Ops. Pressure Temperature Measurement and Compensation |

| Recommended in Gas fluid with Variable Pressure and Temperature | |

| TEMPERATURE PRESSURE CORRECTION | Correction with offset is available |

| FRICTION COEFFICIENT | Cd<24 |

| EXPROOF PROTECTION | Ops. EXD Bt4 |

Advantages

- It is one of the most economical solutions for the measurement of high-pressure fluids.

- It provides high-precision measurement for saturated and superheated steam measurements.

- It is ideal for the economical measurement of gases such as natural gas, biogas, nitrogen, oxygen in continuous flow lines.

- It does not contain any moving parts and it has a long service life.

- The measuring sensor does not come into direct contact with the fluid, which extends the life of the measuring sensor.

- There is no need for physical maintenance other than contamination.

- Can be used horizontally or vertically.

- Its all-metal construction provides an advantage in terms of durability.

- It is protected against corrosion, if necessary, the metal material can be produced differently and used in corrosion fluids.

- It is not affected by vibration.