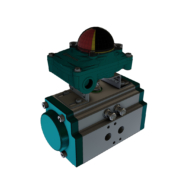

In fluid control systems, being accurate and reliable is key. This is why valve limit switchboxes are important. They help make sure valves work well, which in turn improves the safety and efficiency of industrial processes. This guide will explain why using valve limit switchboxes with pneumatic actuators is a good idea.

WHAT ARE VALVE LIMIT SWITCHBOXES :

A valve limit switchbox is a small device that connects to a pneumatic actuator. Its main job is to tell the control system where the valve is. This information helps control the flow rate and ensures the valve is in the right position.

WHY USE VALVE LIMIT SWITCHBOXES :

- Checking Position: These switchboxes give real-time data on where the valve is—whether it’s fully open, fully closed, or somewhere in between. This helps to prevent mistakes and equipment damage.

- Safety: In high-stakes situations, like handling dangerous materials, knowing the exact position of the valve is crucial. The switchboxes make sure the valves are set up right, reducing the chance of leaks or accidents.

- Remote Checks: The data from these switchboxes can be sent to a control room far away. This allows workers to check the status of valves without having to go to each one, making things more efficient and safe.

- Finding Issues: Any irregularities in how the valve is working, like sticking or jamming, can be quickly spotted by looking at the switchbox data. Catching these problems early helps avoid downtime and expensive repairs.

- Better Processes: Knowing the exact position of valves helps fine-tune operations, which can save energy, improve product quality, and cut down on waste.

WHERE ARE VALVE LIMIT SWITCHBOXES USED :

You’ll find these switchboxes in different sectors like:

- Oil and Gas : They help avoid leaks and keep things running smoothly in pipelines and refineries.

- Water Treatment : They control water and chemical flows in purification plants.

- Chemical Processing : These switchboxes help prevent spills or contaminations by keeping valves in check.

- Power Generation : In power plants, they help control the flow of steam, gases, and other fluids.

- Manufacturing : Here, they help ensure product quality by keeping valves in the right positions.

CONCLUSION :

Valve limit switchboxes are vital for making sure fluid control systems work well. They provide the real-time data needed for safe, efficient operations. Using them with pneumatic actuators can result in better productivity and cost savings.