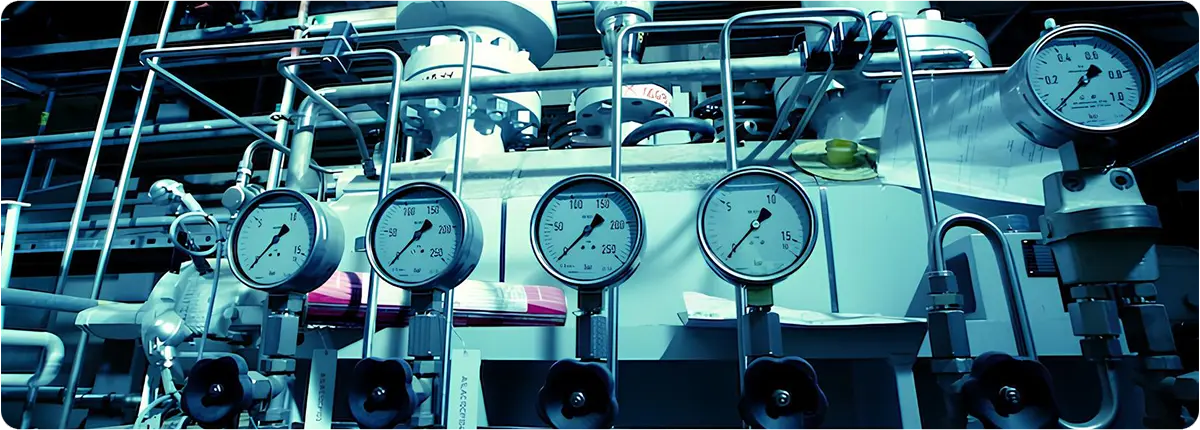

Smart pressure transmitters represent the evolution of traditional pressure measurement devices, integrating advanced sensors, microprocessors, and digital communication protocols. They not only measure pressure but also provide self-diagnostics, remote monitoring, and seamless integration with advanced control systems, enhancing process safety, energy efficiency, and reducing maintenance costs.

WORKING PRINCIPLE

Smart pressure transmitters operate by converting applied pressure into an electrical signal through a diaphragm and sensing element. The most common sensor technologies include:

- Piezoresistive sensors

- Capacitive sensors

- Piezoelectric sensors

- Strain gauge elements

The analog signals are digitized by microprocessors, processed, filtered, and then transmitted to control systems.

Basic equation:

P = F / A

P: Pressure (Pa)

F: Force (N)

A: Area (m²)

STRUCTURAL FEATURES

- High-quality diaphragm materials (stainless steel, tantalum, monel, ceramic)

- Microprocessor-based electronics

- Output protocols: 4-20 mA, HART, Profibus, Fieldbus, Modbus, WirelessHART

- Protection ratings: IP65 – IP68

- Explosion-proof models (ATEX, IECEx)

SMART FUNCTIONS

- Self-diagnosis for malfunction detection

- Predictive maintenance

- Remote monitoring and calibration

- Data logging and trend analysis

- Automatic zero/span adjustment

- Integration with SCADA/DCS systems

SELECTION CRITERIA

- Measurement range and accuracy

- Process environment (temperature, pressure, chemical compatibility)

- Communication protocols

- Certifications (ATEX, SIL, CE)

- Mounting options and mechanical strength

ADVANTAGES AND LIMITATIONS

Advantages:

- High accuracy and long-term stability

- Remote access and data analytics

- Reduced maintenance costs

- Ready for Industry 4.0 and IIoT integration

Limitations:

- Higher initial cost

- Requires specialized configuration

- Cybersecurity risks

APPLICATION AREAS

- Oil and gas industry (pipelines, refineries)

- Chemical plants (reactor pressure monitoring)

- Power plants (boiler and turbine monitoring)

- Food and pharmaceutical industry (hygienic processes)

- Water and wastewater treatment facilities

STANDARDS AND CALIBRATION

- IEC 61508 (SIL certification)

- NAMUR NE107 (diagnostic status)

- ISO/IEC 17025 (calibration)

- Hart and Fieldbus compliance standards

CONCLUSION

Smart pressure transmitters are essential devices for modern industrial automation, combining safety, efficiency, and digitalization. When properly selected and applied, they offer significant long-term benefits to industries.