Understanding Pneumatic Actuators

Pneumatic actuators play an essential role in a multitude of industrial applications, converting compressed air into mechanical motion. These devices come in several designs, but one of the most fundamental distinctions is between single acting and double acting actuators. This guide delves deep into their operation, advantages, and best-fit scenarios.

PNEUMATIC ACTUATORS : THE FUNDAMENTALS

- Functionality: Pneumatic actuators utilize compressed air to produce motion, which can be linear or rotational based on the design.

- Control Mechanism: Actuators respond to pressure differentials in a control system, where compressed air is either introduced or vented from actuator chambers to generate motion.

SINGLE ACTING VS. DOUBLE ACTING ACTUATORS

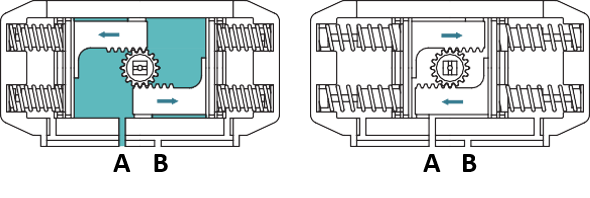

- Single Acting : These actuators use compressed air to move the actuator in one direction (either to open or close). A spring or external force is typically used to return the actuator to its original position. They are often referred to as “spring return” or “fail-safe” actuators because they return to a default position in case of air supply failure.

Air to port A forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.

Air to port A forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.

Loss of air pressure on port A, the stored energy in the springs forces the pistons inwards. The pinion turns clockwise while air is being exhausted from port A.

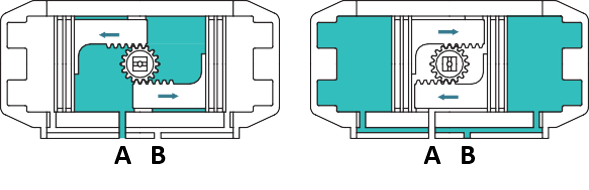

- Double Acting: Double acting actuators use compressed air to move the actuator in both the opening and closing directions. They have two air ports to alternately apply pressure for open and close actions. Without air pressure, a double acting actuator will stay in its last position.

Air to Port A forces the pistons outwards, causing the pinion to turn counterclockwise while the air is being exhausted from Port B.

Air to Port B forces the pistons inwards, causing the pinion to turn clockwise while the air is being exhausted from Port A.

ADVANTAGES OF PNEUMATIC ACTUATORS :

- Energy Efficient: Only require air, making them optimal when air is available.

- Safe: Ideal for explosive environments due to the absence of sparks.

- Cost-Effective: Lower operational costs when compressed air is accessible.

- Rapid Response: Especially with single acting designs, the response time can be swift due to the spring mechanism.

WHERE THEY SHINE :

- Single Acting: Best for safety-critical applications where default positions are vital during failures.

- Double Acting: Essential for processes that require more precise control in both directions and where air supply is consistent.

TECHNICAL CONSIDERATIONS :

- Force & Speed: Pneumatic actuators, especially double acting types, can provide fast actuation. Their force output is determined by the air pressure and actuator size.

- Environmental Suitability: They excel in environments prioritizing cleanliness or safety, devoid of electricity or harmful fluids.

CONCLUSION :

In the realm of actuation, the choice of actuator has profound implications. Pneumatic actuators, specifically the distinction between single and double acting, cater to various applications based on their inherent advantages. A thorough understanding of their mechanics and functionalities enables industries to optimize performance and safety.

Convalve

Convalve Convalve

Convalve