Butterfly Valve

WORKING PRINCIPLE OF BUTTERFLY VALVE

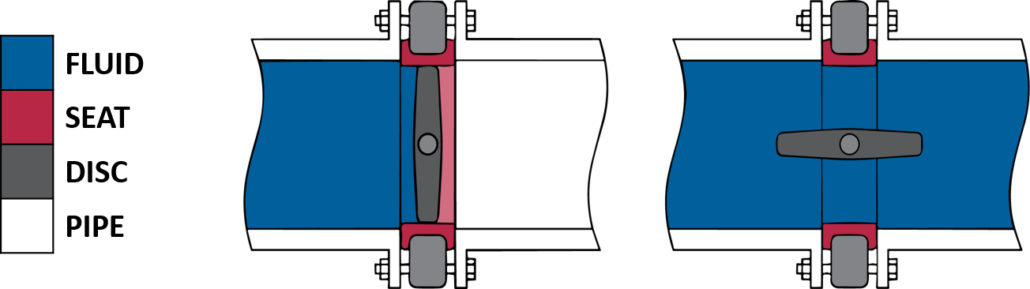

Butterfly valves, known for their simple design, are quarter-turn valves that can be utilized for both on/off and throttling control. They primarily consist of a rotating disc, which is mounted on a shaft. The rotation of this disc, whether parallel or perpendicular to the flow, allows or restricts the flow of the fluid. The valve’s sealing mechanism works by the disc pressing tightly against the valve seat.

Depending on their mounting style, butterfly valves can be classified into:

- Wafer Butterfly Valves: These are sandwiched between pipe flanges, and the connecting bolts encircle the valve body. Wafer butterfly valves are predominantly recommended for low-pressure applications.

- Lug Butterfly Valves: These are quite similar to wafer valves but come with threaded holes. They can be secured from both ends using bolts. Additionally, these can also serve as end-of-line valves.

- Flanged Butterfly Valves: Featuring standard ANSI flanges at both ends, these types of valves are bolted directly to the pipe.

TYPES OF BUTTERFLY VALVE DESIGNS

Butterfly valves can be categorized based on their design into:

- Concentric Design: The most widely used design where the disc rotation is aligned with the stem and pipe axis. They’re economical and apt for water treatment and crude oil systems.

- Double Offset Design: The stem is positioned slightly behind the disc’s centerline, reducing wear and tear during closing. This type finds its application mainly in chemical processes.

- Triple Offset Design: Introducing a third offset, these types of valves minimize wear by allowing minimal contact until the valve is fully closed. They’re primarily used for high-temperature and extreme-pressure scenarios.

ACTUATION METHODS FOR BUTTERFLY VALVES

The operation of butterfly valves can be either manual or automatic:

- Manual Actuation: Often done using hand levers for smaller valves or gearboxes for larger ones.

- Electric Actuation: Uses an electric motor for turning the valve stem, perfect for automated systems.

- Pneumatic Actuation: Employs compressed air for movement, offering fast operation and fail-safe capabilities.

- Hydraulic Actuation: Utilizes hydraulic pressure, suitable for high-pressure scenarios and precise control.

APPLICATIONS OF BUTTERFLY VALVES

From water treatment to food processing, butterfly valves have a plethora of applications:

- Water Treatment: Mainly used for regulating flow.

- Oil and Gas: Control flow in crude oil pipelines.

- Chemical Processing: Ideal for managing flow of chemicals.

- Pharmaceuticals: Precision flow control is vital.

- Food Processing: Their hygienic design makes them apt.

- Fire Protection: Control water flow and pressure effectively.

- HVAC Systems: Regulate flow of air and water.

- Marine: Corrosion-resistant properties come into play.

- General Industrial: For versatile and cost-effective flow control.

CONCLUSION :

Butterfly valves, with their simplicity and reliability, remain a top choice across many industries. Their specific design and actuation method should align with the application’s requirements, considering factors like pressure, temperature, and flow rate.

Convalve

Convalve Convalve

Convalve