Understanding Ball Valves

Ball valves play a pivotal role in controlling fluid flow across numerous sectors. Thanks to their adaptability, trustworthiness, and user-friendliness, they’ve become the go-to for managing the movement of liquids and gases. This guide offers insights into the world of ball valves, spotlighting their types, functioning mechanics, material options, high-pressure usage, automated versions, essential approvals, and their typical industry applications.

COMMON BALL VALVE TYPES :

Ball valves come in a range of designs, each tailored for particular tasks and efficiency demands:

-

- Floating Ball Valve: This type allows the ball to float slightly, with the fluid’s pressure facilitating a seal. Best for low to medium pressures. Commonly found in water supply, irrigation, and general industrial use.

- Trunnion Ball Valve: This valve has a fixed ball held by trunnions. Perfect for high pressures, as it provides extra support, ensuring a tight seal. Typically used in oil, gas, petrochemicals, power generation, and heavy industries.

- V-port Ball Valve: Features a V-shaped ball, allowing precise flow control. Ideal for the chemical sector, food processing, and HVAC systems requiring meticulous flow management.

- Multi-Port Ball Valve: This valve has multiple ports, giving varied flow configurations. They’re frequently utilized in pharmaceuticals, chemical processing, and water treatment.

- Cavity Filled Ball Valve: The ball’s cavity is filled, typically with PTFE, ensuring zero leakage. Primarily used where preventing leaks is paramount, like in chemical processing and petrochemical sectors.

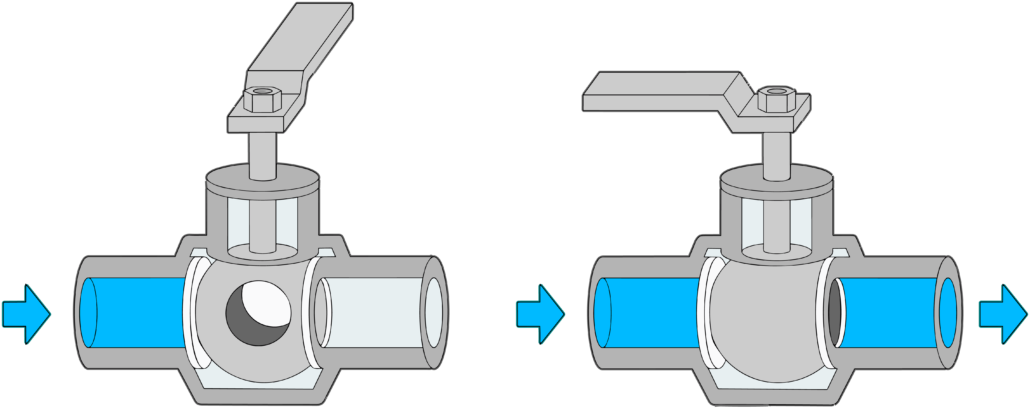

HOW BALL VALVES WORK :

Ball valves operate based on a simple mechanism. They have a ball with a central hole. When open, the hole aligns with the pipeline, permitting fluid passage. When shut, the ball rotates, blocking fluid movement.

MATERIALS AND THEIR PROS & CONS :Actuator a

Different applications demand various materials. Let’s delve into some standard material choices:

-

- Brass:

- Pros: Corrosion-resistant, cost-effective, and widely available.

- Cons: Not ideal for highly corrosive surroundings.

- Stainless Steel:

- Pros: Excellent for high-temperature settings due to its corrosion resistance and durability.

- Cons: Pricier than brass and might not be best for quick temperature shifts.

- Carbon Steel:

- Pros: Durable and suitable for high pressures.

- Cons: Corrosion-prone in certain conditions.

- PTFE (Polytetrafluoroethylene):

- Pros: Highly resilient and chemical resistant.

- Cons: Not the best for high-pressure scenarios.

- Brass:

HIGH-PRESSURE BALL VALVES :

Designed for extreme pressures, these are apt for critical tasks in sectors dealing with aggressive fluids. Trunnion ball valves are a top choice here, often found in the oil, gas, and power generation fields.

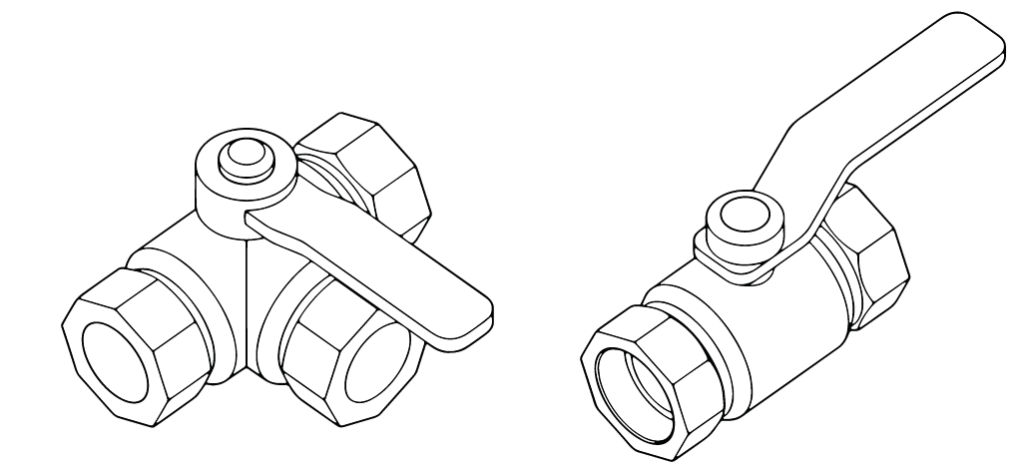

3-WAY VS. 2-WAY BALL VALVES :

-

- 3-Way Ball Valves: With three ports, they’re essential for tasks like mixing or distributing. In HVAC systems, they manage hot and cold water flow.

- 2-Way Ball Valves: Two ports make them ideal for complete shut-off or passage.

AUTOMATED BALL VALVES :

Equipped with actuators for remote handling, these are perfect for industrial tasks, water treatment, and any situation demanding frequent or distant valve management. Electric, pneumatic, or hydraulic actuators can boost efficiency and lessen manual interference.

APPROVALS :

Specific industries might need certifications for safety and standard adherence. Common approvals include API 6D, API 607, ISO 9001, ISO 14001, and CE for Europe.

CONCLUSION :

Ball valves are pivotal in fluid flow management, providing a plethora of choices for diverse applications. Grasping their various forms, operation mechanics, material preferences, and suitability for different pressures ensures professionals make educated valve selections. Be it for general use, high pressures, or automation, the right ball valve promises peak performance, reliability, and security across a variety of domains and tasks.

Convalve

Convalve Convalve

Convalve