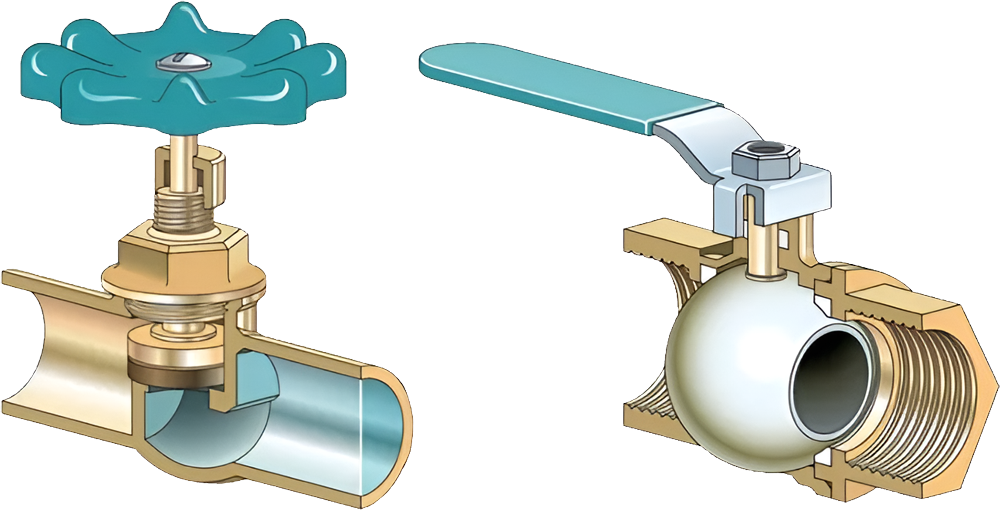

Globe Valve vs. Ball Valve

The fluid control systems within industrial settings make use of various types of valves, each with its unique set of features and advantages. Two of the commonly used types of valves are Globe Valves and Ball Valves. This post aims to compare these two types of valves in a side-by-side manner to facilitate an easier decision-making process:

| Criteria | Globe Valve | Ball Valve |

| Construction and Design | Features a spherical body with a plug-shaped disc and seat, suitable for flow regulation and throttling. | Consists of a spherical closure element (the ball) with a hole (the bore) through its center connected to a stem. |

| Working Principle | Operates by adjusting the plug-shaped disc to throttle or completely shut off the flow. | Works by rotating the ball to align the bore with the flow path, thus allowing or stopping the flow. |

| Advantages | – Excellent for precise flow control – Good sealing capabilities – Versatile applications | – Quick quarter-turn operation – Excellent sealing capabilities – Suitable for both on/off and throttling |

| Disadvantages | – Higher pressure drop – Requires frequent maintenance – Slower to open or close | – May have a higher cost for larger sizes – Not as good for throttling as globe valves |

| Weight (Approximate) | Generally moderate due to intricate internal components. | Heavier, especially in larger sizes, due to the ball and stem construction. |

| Size Range | Available in various sizes but usually more compact than ball valves. | Available in a wide range of sizes, but can be bulkier in larger sizes. |

| Price Range | Typically higher cost due to complex construction and materials for sealing and throttling. | May be less expensive for smaller sizes but can get costly as the size and additional features increase. |

CONCLUSION :

The choice between Globe Valves and Ball Valves depends largely on the application’s specific needs. Globe Valves are excellent for applications requiring precise flow control but come at a higher cost and maintenance needs. On the other hand, Ball Valves offer quick operation and are excellent for both on/off and throttling applications but might be costlier in larger sizes.

By understanding the intricacies of these valves, engineers and operators can make a more informed choice, ensuring optimal performance in fluid control systems.

Convalve

Convalve Convalve

Convalve