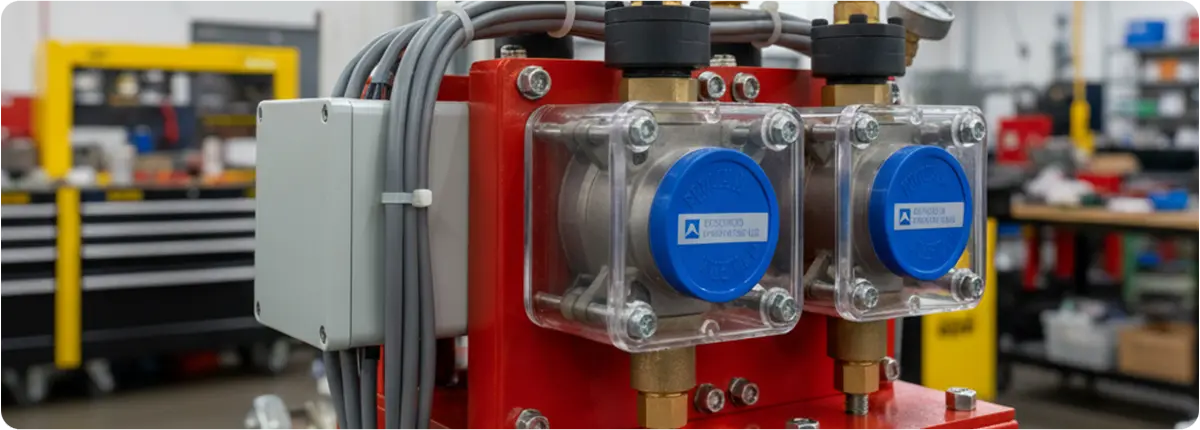

Pressure Switches and Their Industrial Applications

Pressure switches are control devices that open or close an electrical contact when a preset pressure level is reached. Due to their simplicity, they are widely used in both safety and automation applications. From pump protection to industrial process safety, they play a critical role in ensuring reliability.

WORKING PRINCIPLE

When pressure is applied on the diaphragm, it causes mechanical movement that actuates an electrical mechanism. This mechanism results in the opening or closing of contacts. The fundamental principle is based on the relationship between pressure, force, and area:

Formula: P = F / A

Where P: Pressure (Pa), F: Force (N), A: Area (m²).

STRUCTURAL FEATURES

- Body materials: stainless steel, brass, plastic

- Diaphragm materials: NBR, EPDM, stainless steel

- Contact types: NO (normally open), NC (normally closed), SPDT

- Electrical connection options and IP protection classes

TYPES

- Mechanical pressure switches

- Electronic/digital pressure switches (with display, microprocessor controlled)

- Vacuum switches

- Differential pressure switches

SELECTION CRITERIA

- Measurement range (bar, psi)

- Maximum operating pressure

- Contact rating (AC/DC values)

- Process connection (threaded, flanged)

- Environmental conditions (temperature, vibration, humidity, ATEX certification)

ADVANTAGES AND LIMITATIONS

Advantages:

- Simple and reliable operation

- No energy required for mechanical types

- Cost-effective

- Wide application range

Limitations:

- Lower accuracy in mechanical types

- Wear and calibration needs

- Higher cost for electronic models

APPLICATION AREAS

- Pump and compressor protection

- Pressure safety in hydraulic and pneumatic systems

- Boilers and steam systems

- Water treatment plants

- HVAC and automotive applications

STANDARDS

- IEC 60947 (low-voltage switchgear)

- EN 60947-5-1 (switches)

- ATEX certifications (for explosive atmospheres)

CONCLUSION

Pressure switches are cost-effective, reliable, and widely used control devices in critical applications. When properly selected, they provide indispensable protection for equipment and ensure process safety.

Convalve

Convalve Convalve

Convalve