Lug butterfly valves are strong, handy tools for controlling the flow of fluids. They have a special design with lugs (like small hooks) that lets them be easily put in or taken out of pipes without messing up the whole system. This article will explain how they’re built, why they’re good, and where they’re used.

HOW THEY’RE BUILT AND HOW THEY WORK :

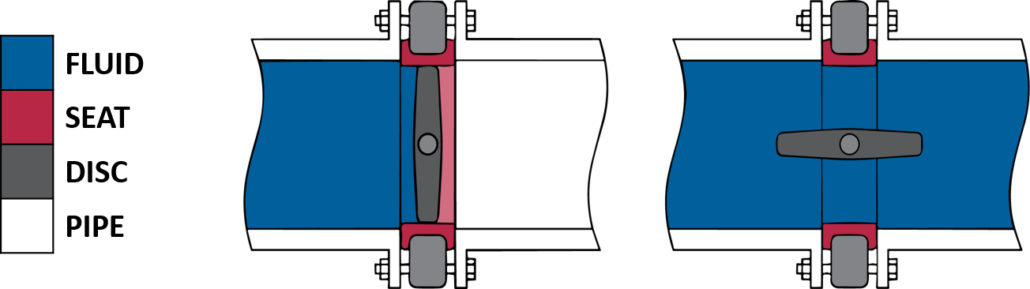

These valves have a disc (think of it like a flap) that can spin inside the main body of the valve. The main body has these lugs on both sides. These lugs are there so the valve can be attached securely between two flanges (connecting points) in a pipe.

When you want fluids to flow, the disc spins to line up with the pipe, and fluids pass through easily. When you want to stop the flow, the disc turns to block the pipe.

WHY THEY’RE GOOD :

- Two-way Sealing: These valves can be put in pipes in any direction and still work perfectly.

- Quick to Install or Take Out: Because of the lugs, you can easily add or remove the valve without taking apart the whole pipe system.

- Small and Light: These valves don’t take up much space and aren’t heavy. This is good for places where there isn’t much room and makes them cheaper to move around.

- Saves Money: They’re simpler to make and put in, so they often cost less than other kinds of valves.

WHERE THEY’RE USED :

- Chemical Plants: They’re used here because they seal really well and can be trusted to stop and start flow when needed.

- Cleaning Water: These valves are used in places that treat water and manage wastewater since they’re easy to use and seal both ways.

- Boats and Ships: They help control water and fuel flow in marine settings.

- Making Electricity: Especially in places that need to control the flow of cooling water or air.

- Putting Out Fires: They’re in fire systems because they can quickly stop or start the flow of water.

CONCLUSION :

Lug butterfly valves are a great choice for controlling fluid flow in many areas because they’re easy to use, efficient, and won’t break the bank. Whether you’re in the chemical business, water treatment, shipbuilding, power making, or even fire safety, these valves are key in managing fluids the right way.