In industrial facilities, efficiency, safety, and product quality depend heavily on the ability to measure, monitor, and control process variables. The systems designed for this purpose are known as measurement and control systems. From oil and gas refineries to food production plants, from power generation facilities to wastewater treatment, these systems form the backbone of industrial automation.

By implementing advanced measurement and control systems, plants achieve:

– Improved energy efficiency

– Standardized product quality

– Enhanced operational safety

– Reduced environmental impact.

THE IMPORTANCE OF MEASUREMENT AND CONTROL SYSTEMS

Every industrial process operates within a defined range of parameters. Deviations in pressure, temperature, flow, or level can result in energy waste, equipment damage, production losses, and even safety hazards. For this reason, measurement and control systems are often referred to as the ‘heart’ of industrial operations.

CORE COMPONENTS AND OPERATING PRINCIPLE

A measurement and control system typically consists of three main components:

Sensors / Transducers: Convert physical quantities into electrical signals (e.g., thermocouples, pressure transmitters, ultrasonic level sensors).

Controllers: Compare measured values with set points and generate control signals (e.g., PLCs, DCS, PID controllers).

Final Control Elements: Act directly on the process (e.g., control valves, actuators, motors).

Principle: The chain of Sensor → Controller → Final Control Element establishes the feedback loop that keeps the process stable.

CONTROL THEORY AND PID REGULATION

The most widely used algorithm in process industries is the PID controller, expressed by:

u(t) = Kp * e(t) + Ki ∫ e(t) dt + Kd * de(t)/dt

• e(t): Error signal (set point – measured value)

• Kp: Proportional gain (fast reaction)

• Ki: Integral gain (eliminates steady-state error)

• Kd: Derivative gain (responds to sudden changes)

Example: In a chemical reactor, poor PID tuning may cause runaway exothermic reactions, risking both product quality and plant safety.

KEY PROCESS VARIABLES

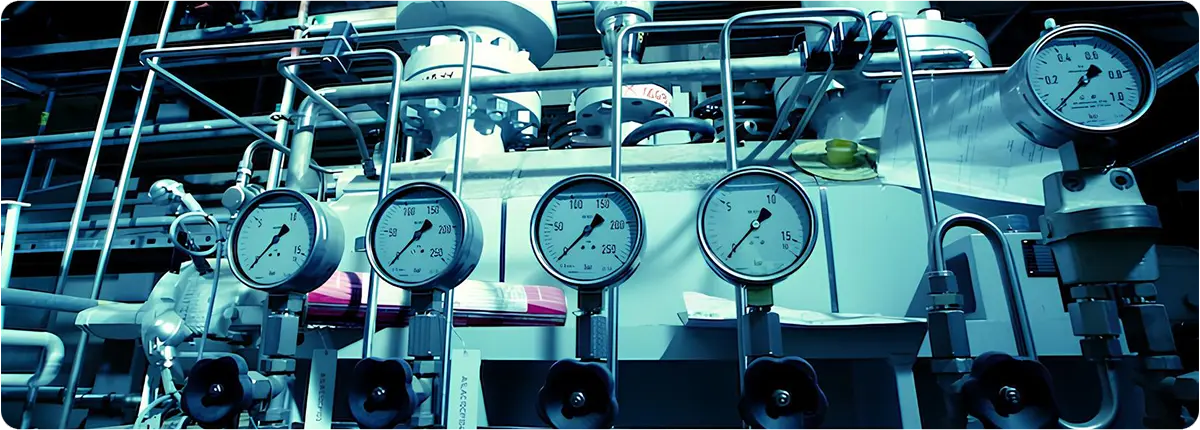

Pressure Measurement: Devices include Bourdon gauges, strain gauge sensors, and differential pressure transmitters.

Formula: P = F / A (Force per unit area)

Flow Measurement: Techniques include orifice plates, Venturi tubes, ultrasonic and magnetic flowmeters.

Fundamental relation: Q = A * v (Flow = cross-sectional area × velocity)

Temperature Measurement: Methods include thermocouples (Seebeck effect), RTDs (resistance change), and infrared sensors.

RTD relationship: R(T) = R0 * (1 + α * ΔT)

Level Measurement: Techniques include float, hydrostatic pressure, radar, and ultrasonic sensors.

Hydrostatic formula: h = P / (ρ * g)

INDUSTRIAL APPLICATIONS

Petrochemical Industry: Pressure and temperature control in distillation columns.

Power Plants: Boiler drum level and steam pressure regulation.

Food and Beverage: Pasteurization systems requiring precise temperature and flow control.

Water Treatment: Tank level monitoring and pH regulation in wastewater plants.

STANDARDS AND SAFETY REQUIREMENTS

Compliance with international standards is essential for reliability and safety:

– IEC 61511: Safety systems for process industries

– ISO 5167: Flow measurement standards

– ASME & API standards: Specific rules for oil and gas operations

CONCLUSION

Without measurement and control systems, modern industries could not operate safely or efficiently. Proper sensor selection, accurate controller tuning, and reliable final control elements are the foundation of industrial automation.

In the upcoming articles of this series, we will explore pressure, flow, temperature, and level measurement systems in greater technical depth.