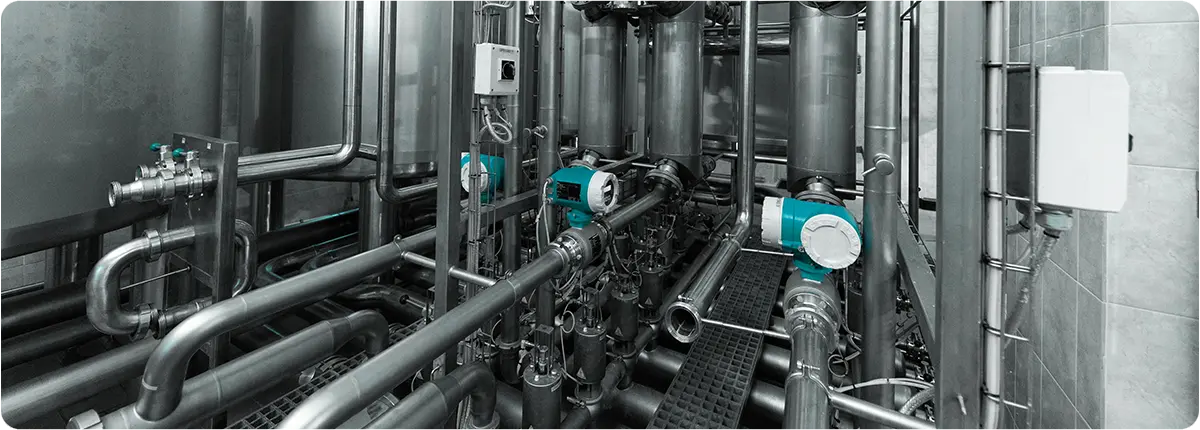

Metal tube flowmeters are robust instruments designed for accurate flow measurement under high pressure, high temperature, and aggressive fluid conditions. Compared to glass tube rotameters, they offer greater durability and are widely used in chemical, petrochemical, power generation, water treatment, food, and pharmaceutical industries.

WORKING PRINCIPLE

They operate on the variable area principle. As the fluid flow increases, the float rises. In metal tube designs, the float position is detected either by magnetic sensors or mechanical indicators.

Fundamental equation:

Q = C · A(h) · √(2ΔP / ρ)

Q: flow rate, C: coefficient, A(h): cross-sectional area depending on float position, ΔP: pressure drop, ρ: fluid density.

STRUCTURAL FEATURES

- Measuring tube: stainless steel or alloy steel

- Float: selected with different densities for higher accuracy

- Indicators: Mechanical (pointer type) or electronic (4-20 mA, HART, Profibus)

- Operating range: up to 100 bar pressure and 400 °C temperature

ADVANTAGES AND LIMITATIONS

Advantages:

- Reliable under harsh process conditions

- Suitable for both liquids and gases

- Easy integration with automation systems through electronic outputs

Limitations:

- More expensive than glass tube models

- Limited direct visual observation, relies on indicators

APPLICATION AREAS

- Acid/alkali measurement in chemical and petrochemical plants

- Steam and condensate flow monitoring in power plants

- Chemical dosing control in water treatment facilities

- Hygienic process monitoring in food and pharmaceutical industries

STANDARDS AND CALIBRATION

- ISO 5167: Flow measurement standards

- ASME MFC: Standards for flow measurement devices

- ATEX-certified versions: For explosive atmospheres

- Regular calibration required to maintain accuracy

CONCLUSION

Metal tube flowmeters play a vital role in modern industry due to their durability and reliability. By combining with digital technologies, they can be seamlessly integrated into automation systems, contributing to process optimization and efficiency.