Natural gas plays a vital role in meeting the world’s energy demand, and its safe transmission depends heavily on the performance of valves installed in pipelines. Valves regulate flow, control pressure, isolate sections of the pipeline, and provide emergency shutdown capabilities. Choosing the wrong type of valve not only reduces efficiency but can also lead to severe safety risks.

This article examines the types of valves used in natural gas pipelines, their features, material and standard requirements, and key factors engineers must consider when selecting them.

MAIN VALVE TYPES IN NATURAL GAS PIPELINES

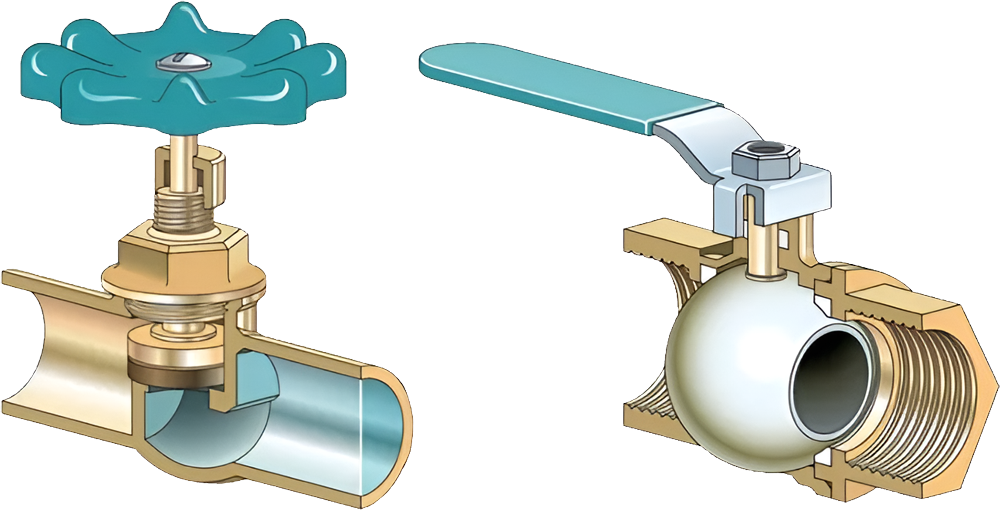

Ball Valves

- The most widely used valves in natural gas systems.

- Advantages: Full-bore design minimizes pressure drop. Operated with a quarter-turn (90°), making them ideal for emergency shutoff.

- Applications: Commonly used in long-distance transmission pipelines and city gate stations.

Gate Valves

- Preferred in large-diameter transmission lines.

- Advantages: Minimal flow resistance when fully open.

- Disadvantages: Slower to operate compared to ball valves.

- Example: Frequently installed in 36” and larger pipeline sections.

Butterfly Valves

- Compact and cost-effective solutions for large-diameter lines.

- Advantages: Lightweight, simple construction, and economical.

- Applications: More common in distribution networks operating at medium pressure.

Control Valves

- Designed to regulate flow rate and pressure.

- Features: Can be integrated into SCADA and automation systems.

- Example: LNG terminals rely on control valves for continuous adjustment of gas flow.

Safety and Relief Valves

- Protect pipelines from overpressure events.

- Operation: Open at a preset pressure, venting gas to the atmosphere.

- Standard: Designed according to API 520/521.

Check Valves

- Prevent reverse flow, protecting compressors and downstream equipment.

- Example: A standard component in compressor stations.

MATERIAL SELECTION AND STANDARDS

- Common Materials:

- Carbon steel (ASTM A105, A216 WCB)

- Low-temperature steels (ASTM A350 LF2)

- Stainless steels (AISI 304, 316) for corrosive environments

- Relevant Standards:

- API 6D – Pipeline valves

- ASME B16.34 – Pressure-temperature ratings

- ISO 14313 – International pipeline valve standard

KEY SELECTION CRITERIA

Pressure Class

Valves are designed according to ANSI classes ranging from 150 to 2500.

Example: A 70-bar transmission pipeline typically requires a Class 600 valve.

Flow Coefficient (Cv)

The capacity of a valve is defined by its flow coefficient:

Q = Cv · √(ΔP / G)

- Q: Flow rate (m³/h)

- ΔP: Pressure drop (bar)

- G: Specific gravity of gas

Temperature and Operating Conditions

- Natural gas is usually transported between -20 °C and +60 °C.

- Valve seals and body materials must be compatible with this range.

Automation and Remote Control

- Critical stations require actuated valves (electric, pneumatic, or hydraulic).

- Example: City gate stations often use pneumatically actuated ball valves integrated into SCADA.

Safety and Maintainability

- Valves with Double Block & Bleed (DBB) design improve maintenance safety.

- They also allow testing of pipeline segments under pressure.

REAL-WORLD APPLICATIONS

- TANAP Project (Turkey): The 1,850 km Trans-Anatolian Natural Gas Pipeline relies on API 6D ball valves for high-pressure transmission.

- European Distribution Networks: Medium-pressure networks frequently use butterfly and control valves.

- Compressor Stations: Check valves are indispensable to prevent backflow damage.

CONCLUSION

Valves in natural gas pipelines are essential for safety, efficiency, and operational continuity. From ball and gate valves to butterfly, control, and relief valves, the selection depends on pipe diameter, pressure class, flow capacity, and automation requirements.

Improper valve selection can result in high operational costs or serious safety hazards. Therefore, engineers must rely on API, ASME, and ISO standards, ensuring each valve is designed and chosen for the specific conditions of the pipeline.