Vortex Flowmeters and Industrial Applications

Vortex flowmeters are instruments that measure flow by detecting the frequency of vortices shed by a bluff body placed in the flow stream. Based on the Kármán vortex street principle, they are widely used for liquids, gases, and steam measurement. Their reliability, broad application range, and lack of moving parts make them highly valuable in industrial processes.

WORKING PRINCIPLE

As fluid passes a bluff body in the pipe, vortices are shed alternately at regular intervals. The frequency of these vortices is directly proportional to the flow velocity.

Basic equation:

f = St · v / d

f: vortex frequency (Hz), St: Strouhal number (dimensionless), v: fluid velocity (m/s), d: bluff body width (m).

Flow rate is then calculated as:

Q = v · A

Q: flow rate (m³/s), A: pipe cross-sectional area (m²).

STRUCTURAL FEATURES

- Bluff body: generates vortices

- Sensors: piezoelectric, capacitive, or ultrasonic detection

- Body: stainless steel or alloy materials

- Output signals: Pulse, 4-20 mA, HART, Modbus, Profibus

- Can be equipped with pressure and temperature compensation

ADVANTAGES AND LIMITATIONS

Advantages:

- No moving parts, minimal maintenance

- Suitable for liquids, gases, and steam

- Can operate under high temperature and pressure

- Wide measurement range

Limitations:

- Cannot measure accurately at low Reynolds numbers (Re < 2000)

- Sensitive to vibrations and noise

- Accuracy decreases at low flow rates

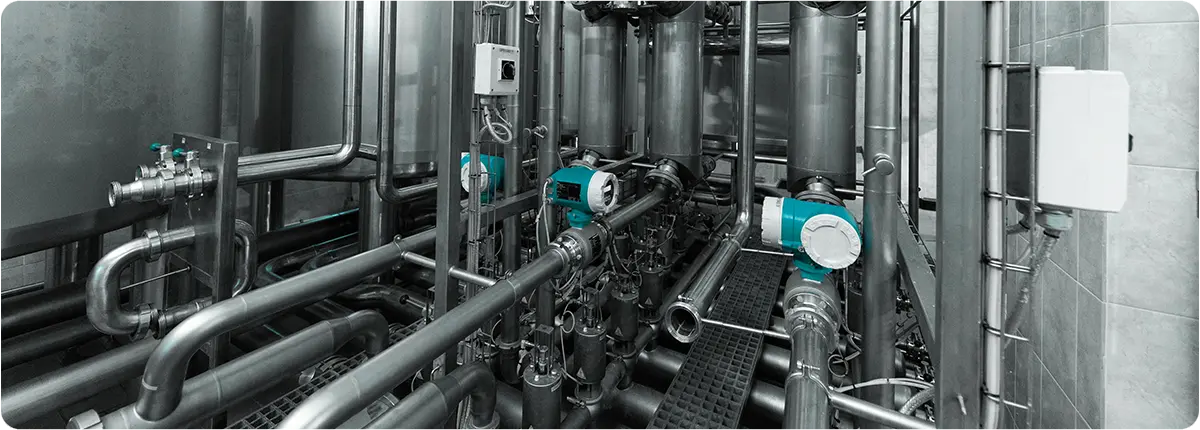

APPLICATION AREAS

- Steam measurement in power plants

- Flow control in natural gas distribution networks

- Process monitoring in chemical and petrochemical industries

- Flow measurement in water and wastewater facilities

- Liquid flow monitoring in food and beverage production

STANDARDS AND CALIBRATION

- ISO 5167: Standards for flow measurement devices

- ASME MFC-6: Standards for testing and calibration of vortex meters

- AGA reports: Guidelines for gas flow measurement applications

- Regular calibration is necessary to maintain accuracy

CONCLUSION

Vortex flowmeters are robust, versatile, and low-maintenance instruments widely used in modern industries. Their ability to integrate with digital communication protocols makes them a key component in process automation and industrial monitoring systems.

Convalve

Convalve Convalve

Convalve