High-Performance Valves for the Mining Industry: Durability in the Toughest Conditions

THE HARSH DEMANDS OF THE MINING INDUSTRY

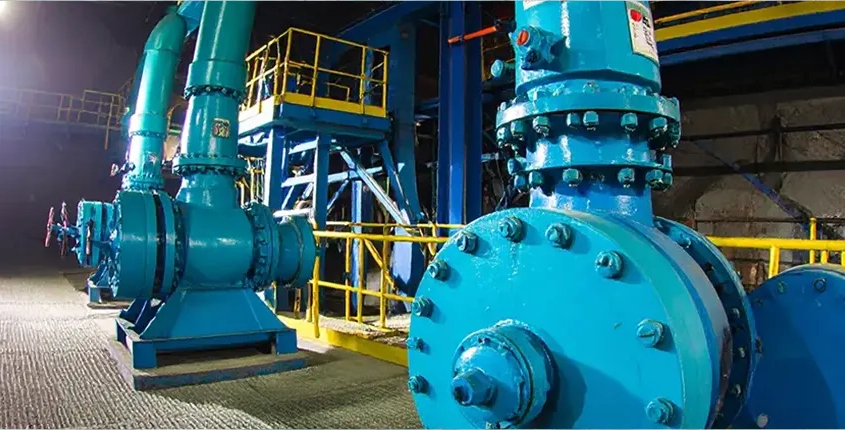

The mining industry operates under some of the most extreme conditions found in any sector. From abrasive slurries and corrosive chemicals to high pressures and extreme temperatures, every component in a mining operation must withstand intense wear and tear. Valves, as critical control points in fluid handling systems, are particularly vulnerable to these challenges.

In mining applications, the fluids being transported often contain high concentrations of solids, sand, and chemicals that can quickly erode or corrode poorly designed valves. That’s why selecting the right valve is not just important—it’s essential to ensure operational efficiency, worker safety, and reduced downtime.

VALVE TYPES AND SELECTION FOR MINING APPLICATIONS

Several valve types are used in the mining industry, each suited to specific roles:

- Knife Gate Valves – Designed for handling slurries, these valves cut through solid-laden flow and provide tight shut-off.

- Ball Valves – Ideal for on/off control in clean or mildly abrasive fluids; available in hardened materials for mining conditions.

- Butterfly Valves – Lightweight, easy to operate, and perfect for large-diameter pipelines in non-slurry services.

- Check Valves – Prevent backflow and protect pumps and critical equipment.

- Pressure Relief Valves – Protect the system from dangerous overpressure events.

When selecting mining valves, engineers must consider:

- Abrasion Resistance – Materials like hardened stainless steel or specially coated alloys resist wear from solid particles.

- Corrosion Resistance – Essential when handling acidic or chemically treated fluids.

- Pressure and Temperature Ratings – Must align with operating conditions.

- Maintenance Access – Valves should be serviceable without prolonged downtime.

CONVALVE’S PROVEN TRACK RECORD IN MINING PROJECTS

Convalve has supplied high-performance valves to mining operations around the world for decades. Our products are trusted in large-scale projects such as:

- Copper and gold mines in South America, where our knife gate valves handle abrasive slurries with minimal maintenance.

- Iron ore facilities in Australia using Convalve butterfly valves in their water supply and processing systems.

- Coal mining operations in South Africa relying on our ball valves for durable and leak-free control.

Our valves are built with premium materials, precision machining, and advanced sealing technologies to deliver exceptional longevity, even in the most punishing environments. For mining operations that demand reliability, Convalve valves are the proven choice—ensuring safe, efficient, and uninterrupted production.

Convalve

Convalve