Manual angle seat valves serve as fundamental elements in fluid control systems. They ensure effective and accurate flow regulation for a myriad of industrial applications. Given their manual operation, they permit easy control over the flow of various media, such as liquids, gases, and steam. This piece delves into the construction, operational dynamics, perks, and application areas for manual angle seat valves.

CONSTRUCTIVE INSIGHTS :

- Sturdy Make: Manual angle seat valves are durable, primarily fashioned from resilient materials like stainless steel or brass. Their special angled seat design facilitates an unhindered flow, leading to minimal pressure losses when the valve stands open.

- User-Friendly Actuator: The manual actuator, positioned at the valve’s zenith, boasts a design that is simple to use and understand.

OPERATIONAL DYNAMICS :

- Default State (Closed): Initially, the valve’s closing component seals itself against the angled seat, halting fluid flow.

- Activation (Open Up): Fluid flow is enabled when the actuator is turned, lifting the closing component from the seat.

- Deactivation (Shut Down): Turning the actuator in the opposite direction makes the closing component reseat, terminating fluid flow.

WHY CHOOSE MANUAL ANGLE SEAT VALVES ?

- Effortless Usage: With a design geared towards simple handling, they fit perfectly where manual oversight is required.

- Budget-Friendly: Absent the need for extra pneumatic or electric parts, these manual valves emerge as cost-effective fluid control tools.

- Consistency: They guarantee stable and reliable flow control, solidifying process consistency.

- Zero Power Dependency: Their manual nature means they don’t hinge on external energy sources. This is a boon for areas with limited or no power access.

WHERE ARE THEY USED ?

From labs to large-scale industries, the reach of manual angle seat valves is broad:

- Mini Industrial Setups: Best suited for manual flow governance in compact industrial zones or pilot facilities.

- Research Labs: Laboratories prize them for their precision and simplicity in fluid control.

- Water Treatment: They feature prominently in water treatment facilities for manually overseeing chemical dosing and flow metrics.

- Textile Realm: They find a niche in controlling flow during dyeing or printing processes in the textile sector.

- Diverse Industries: Their footprint is visible across many industries, standing out as reliable tools for manual fluid control.

CONCLUSION :

Offering versatility and efficiency in fluid control, manual angle seat valves are a favored pick across diverse scales and sectors. Their ease of use, affordability, and precision make them a coveted asset for manifold processes. Integrating these into fluid control frameworks empowers operators with refined control, ease, and consistency.

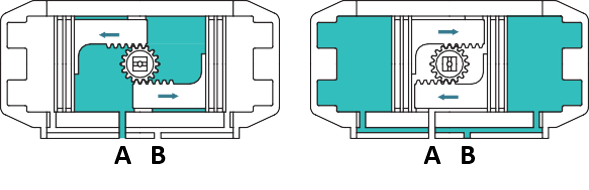

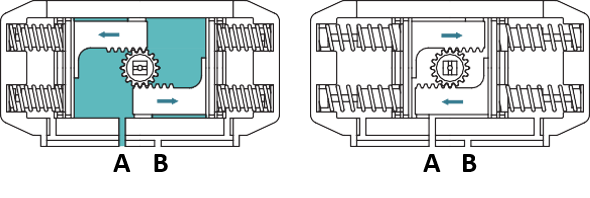

Air to port A forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.

Air to port A forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.