As the weather turns cold, it’s critical to think about how freezing conditions can affect valves in various systems. Valves play a key role in controlling fluids and their optimal performance is necessary for efficient operations—even in winter. This guide covers the significance of antifreeze measures and winter maintenance for valves, helping you ensure they function well during colder months.

UNDERSTANDING FREEZING RISKS :

Cold weather can freeze and expand any remaining water or fluids in valves, potentially causing damage. Ice buildup can put a lot of pressure on valve parts, resulting in leaks, cracks, or even total failure. This is especially concerning for outdoor setups, pipelines, HVAC units, and industrial systems.

ANTIFREEZE MEASURES :

To protect valves from cold damage, consider these antifreeze steps:

- Insulation: Wrap valves and pipelines to reduce heat loss and avoid freezing.

- Drainage: Make sure pipelines and valves are properly drained to remove any leftover water that could freeze.

- Heat Tracing: Use heat cables to maintain a consistent temperature in crucial areas.

- Antifreeze Fluids: Add antifreeze or glycol-based liquids into systems likely to be exposed to freezing temperatures.

- Enclosures: Put up enclosures around valves for extra protection against the cold.

WINTER MAINTENANCE FOR VALVES :

Routine care is essential for valve functionality during winter:

- Regular Checks: Look for signs of freezing damage or leaks during visual inspections.

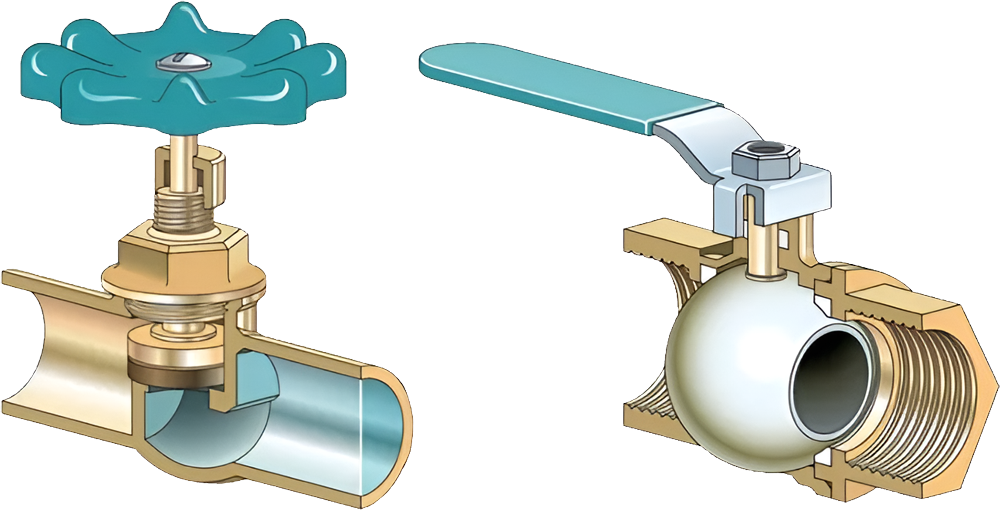

- Lubrication: Use suitable lubricants on valve parts for smooth operation in cold weather.

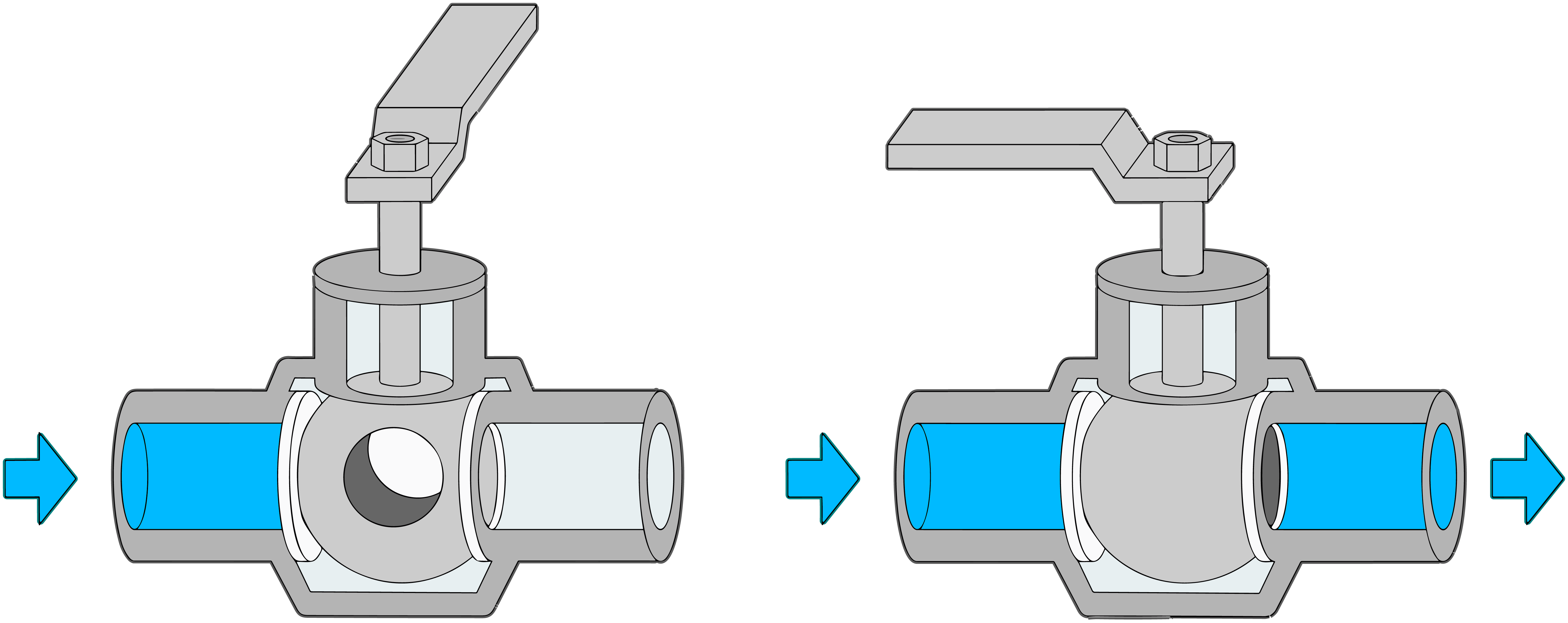

- Functional Tests: Periodically operate the valves to keep them from freezing due to inactivity.

- Cleaning: Get rid of ice, snow, or other obstructions from valve parts for optimal performance.

- Monitoring: Use temperature sensors to keep an eye on temperature changes and act quickly if needed.

CUSTOMIZED APPROACHES FOR DIFFERENT NEEDS :

Each system has its own requirements, and antifreeze and maintenance methods may differ:

- Home Systems: Take care of outdoor valves in watering systems, pool setups, and water supplies to avoid freezing and harm.

- Industrial Setups: Create detailed antifreeze plans in factories, chemical units, and oil refineries to avoid expensive downtime.

CONCLUSION :

Preparing valves for winter is vital for uninterrupted operation and avoiding costly repairs. By implementing antifreeze measures like insulation, proper drainage, and regular maintenance, you can ensure that your valves keep working effectively even in extreme cold. Tailoring your approach to your system’s specific needs allows for reliable and efficient fluid control, no matter how harsh the winter weather becomes.